Wastewater Wash Station

Parts Washing Stations

PWS Parts Washing Stations

Portable Closed-Loop with Biological Treatment for Recycling Wash WaterThese portable wastewater wash stations meet virtually any parts cleaning requirement. Parts washers are used to remove grease, oil, dirt, soot and other contaminants from surfaces. One advantage to our parts washing station is that the compact size allows for portability. Wastewater parts wash station come with forklift slot for easy transport. Four standard wash area dimensions afford a range of operating needs to handle different parts sizes, dimensions, and geometries.

- Electrical Requirements: 240 Volt/ 1 Phase (30 Amps)

- Wash Deck Load Capacity: 4,500 lbs.

- Wash Water Flow Range: 0-15 GPM

- Pressure Pump: ¾ HP

- Regenerative Blower: 1.0 HP

- Biological Media: 752 sq ft

- Wall Height (3 Sides): 4 Ft

- Filtration: Reusable pleated poly 25 micron – 47 sq ft

- Construction: Marine Grade Aluminum

- Water Supply: ¾ “ fresh water with valve for auto-fill

- Options: 40” or 50” diameter turntable (3500 lb capacity), splash curtains (front), pressure washer (1000 PSI @ 2.2 GPM). Call for pricing.

- Warranty: One Year Parts and Labor

| MODEL | DESCRIPTION | DAILY CAPACITY | WEIGHT | PRICE |

| WW-PWS-56 | 5' x 6' Wastewater Parts Wash Station | 950 gallons | 1300 lbs | Call for Pricing |

| WW-PWS-58 | 5' x 8' Wastewater Parts Wash Station | 1,050 gallons | 1450 lbs | Call for Pricing |

| WW-PWS-510 | 5' x 10' Wastewater Parts Wash Station | 1,050 gallons | 1600 lbs | Call for Pricing |

| WW-PWS-512 | 5' x 12' Wastewater Parts Wash Station | 1,250 gallons | 1750 lbs | Call for Pricing |

Installation and Service

With a talented service team that is second to none, Ultimate Washer can arrange the installation and service of your wastewater wash station to maximize the system operation and performance. Installation, Start Up and Training is necessary.

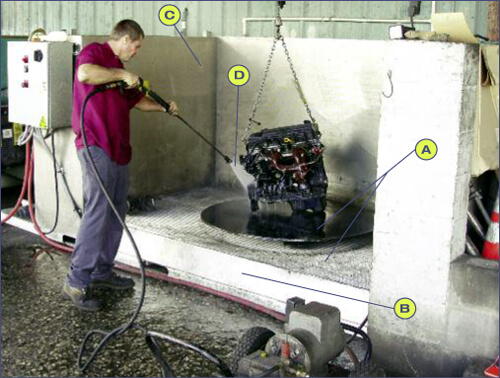

A- Wash Platform and Turntable

Items to be washed can be placed directly on the 4,500 lb. load capacity grated wash platform, or on the optional 3,500 lb. capacity, rotating turntable. The operator is able to stand next to the wash pad during the entire washing operation.

B- Wash Pad

Wash water from the washing operation cascades through the grates and into the wash pad containment area where the water flows through a maze of channels to a sump area in the wash pad. Larger solid material is dropped out of the waste stream and a sump pump delivers the water to the first chamber of the biological treatment unit.

C-Biological Treatment Unit

A compact biological treatment unit is an integral component of the parts washing station. The biological treatment unit is designed to direct the wash water through multiple chambers containing hundreds of square feet of honeycomb bio-media with billions of specially formulated microbes. Organic constituents in the wash water, such as oils, greases and fuels, are consumed by the microbes and the organic contaminants are converted into carbon dioxide and water. A final 25 micron pleated and reusable filter removes any articulate load before feeding the pressure washer.

D- Recycled Wash Water

Treated water is delivered in a closed-loop environment from the biological treatment unit to either: a. an optional self-contained 1,000 psi, 2.2 GPM pressure washer systems, or b. to a standard hot or cold water pressure washer of your choice. The process then begins again.